What are the types of Conductors used in Overhead Power Lines…

- It has maximum electrical conductivity

- It has high tensile strength so that it can withstand mechanical stresses

- It has least specific gravity i.e. weight / unit volume

- It has least cost without sacrificing other factors

- It has lesser cost than copper.

- It offers larger diameter for same amount of current which reduces corona.

- It has lesser conductivity

- It has larger diameter which increase surface area to air pressure thus it swings more in air than copper so larger cross arms required which increases the cost.

- It has lesser tensile strength ultimately larger sag

- It has lesser specific gravity (2.71gm/cc) than copper (8.9 gm/cc) cc = cubic centimeter

- Due to lower tensile strength aluminium is used with some other materials or its alloys

- It has lesser strength and more sag per span length than any other category

- Therefore, it is used for lesser span i.e. it is applicable at distribution level

- It has slightly better conductivity at lower voltages than ACSR i.e. at distribution level

- Cost of ACSR is equal to AAC.

- It is cheaper than AAAC but pro to corrosion.

- It is most expansive.

-

- It has same construction as AAC except the alloy.

- Its strength is equal to ACSR but due to absence of steel it is light in weight.

- The presence of formation of alloy makes it expensive.

- Due to stronger tensile strength than AAC, it is used for longer spans.

- It can be used in distribution level i.e. river crossing.

- It has lesser sag than AAC.

- The difference between ACSR and AAAC is the weight. Being lighter in weight, it is used in transmission and sub-transmission where lighter support structure is required such as mountains, swamps etc.

- It is used for longer spans keeping sag minimum.

- It may consist of 7 or 19 strands of steel surrounding by aluminium strands concentrically. The number of strands are shown by x/y/z, where ‘x’ is number of aluminium strands, ‘y’ is number of steel strands and ‘z’ is diameter of each strand.

- Strands provide flexibility, prevent breakage and minimize skin effect.

- The number of strands depends on the application, they may be 7, 19, 37, 61, 91 or more.

- If the Al and St strands are separated by a filler such as paper then this kind of ACSR is used in EHV lines and called Expanded ACSR.

- Expanded ACSR has larger diameter and hence lower corona losses.

-

- It is 100 % pure conductor and it is standard for reference.

- For 36 kV transmission and above both aluminium conductor steel reinforced (ACSR) and all aluminium alloy conductor (AAAC) may be considered. Historically ACSR has been widely used because of its mechanical strength, the widespread manufacturing capacity and cost effectiveness.

- From a materials point of view the choice between ACSR and AAAC is not so obvious and at larger conductor sizes the AAAC option becomes more attractive. AAAC can achieve significant strength/weight ratios and for some constructions gives smaller sag and/or lower tower heights. With regard to long-term creep or relaxation, ACSR with its steel core is considerably less likely to be affected.

- Jointing does not impose insurmountable difficulties for either ACSR or AAAC types of conductor as long as normal conductor cleaning and general preparation are observed. AAAC is slightly easier to joint than ACSR.

- Historically there has been no standard nomenclature for overhead line conductors, although in some parts of the world code names have been used based on animal (ACSR – UK), bird (ACSR – North America), insect (AAAC – UK) or flower (AAAC – North America) names to represent certain conductor types.

- Aluminium-based conductors have been referred to by their nominal aluminium area. Thus, ACSR with 54 Al strands surrounding seven steel strands, all strands of diameter d 3.18 mm, was designated 54/7/3.18; alu area 428.9 mm2, steel area 55.6 mm2 and described as having a nominal aluminium area of 400 mm2.

Why Lighting transformers are used ?

(2 Min Read)

- Lighting Transformers are designed to supply power to lighting equipment in a commercial / industrial / domestic unit.

- Lighting transformers serves as isolation between primary and secondary, it also restricts any high voltage spikes and EMF coming with the raw mains incoming power.

- The prime reason for using Lighting transformer is to reducing the fault level of the lighting installation where the wires/switch gears used would have a lesser short time withstand rating.

- Another reason is to isolate the other loads like motors etc from lighting loads which basically operate on single phase supply and hence prone to unbalance as well as ground faults. so its better to use a isolation transformer having ration 1:1, it will provide the complete isolation to the equipment which is connected to PCC/MCC.

- It is also used where incoming supply is 3 phase 3 wire and lighting load is 220 Volt single phase.

Why Relay often has two ratings AC and DC...? How to choose the correct one ...???

The contacts in a relay (and the same is true for other switches) have to be able to safely and repeatedly allow and interrupt the rated current.

Interrupting is hard on the contacts, since there is always some inductance in the circuit, which creates a high voltage when the current is interrupted. This voltage causes a spark (continued current flow) when the contacts open, and gradual damage to the contact surfaces. If the contacts are too close, and the circuit can supply a high enough voltage, the spark may continue a long time.

In DC circuits the spark is only extinguished when the contacts are far enough apart. The higher the voltage of the circuit, the bigger the contact gap has to be. In AC circuits this spark stops naturally because voltage and current reduce to zero twice per AC cycle, so for a given contact separation a much higher circuit voltage can be tolerated.

How to calculate for the Correct Relay

Relay Ratings and Limits

Relays often have two ratings: AC and DC. These rating indicate how much power can be switched through the relays. This does not necessarily tell you what the limits of the relay are. For instance, a 5 Amp relay rated at 250 VAC can also switch 10 Amps at 125VAC. Similarly, a 5 Amp relay rated at 48 VDC can switch 10 Amps at 24VDC, or even 20 Amps at 12VDC.

Volts x Amps = Watts - Never Exceed Watts!

An easy way to determine the limit of a relay is to multiply the rated Volts times the rated Amps. This will give you the total watts a relay can switch. Every relay will have two ratings: AC and DC. You should determine the AC watts and the DC watts, and never exceed these ratings.

Example Calculations:

AC Volts x AC Amps = AC Watts

DC Volts x DC Amps = DC Watts

Example:

A 5 Amp Relay is Rated at 250 Volts AC.

5 x 250 = 1,250 AC Watts

Example:

A 5 Amp Relay is Rated at 24 Volts DC.

5 x 24 = 120 DC Watts

If you are switching AC Devices, Make Sure the AC Watts of the Device you are Switching DOES NOT Exceed 1,250 when using a 5A Relay.

If you are switching DC Devices, Make Sure the DC Watts of the Device you are Switching DOES NOT Exceed 120 when using a 5A Relay.

Resistive and Inductive Loads

Relays are often rated for switching resistive loads. Inductive loads can be very hard on the contacts of a relay. A resistive load is a device that stays electrically quiet when powered up, such as an incandescent light bulb. An inductive load typically has a violent startup voltage or amperage requirement, such as a motor or a transformer.'

Startup and Runtime Loads

Inductive loads typically require 2-3 times the runtime voltage or amperage when power is first applied to the device. For instance, a motor rate at 5 Amps, 125 VAC will often require 10-15 amps just to get the shaft of the motor in motion. Once in motion, the the motor may consume no more than 5 amps. When driving these types of loads, choose a relay that exceeds the initial requirement of the motor. In this case, a 20-30 Amp relay should be used for best relay life.

When the relay opens it will draw an arc. With AC power the current drops to zero 100 or 120 times per second (depending on whether you have 50Hz or 60Hz power), and this will allow the arc to extinguish. With DC power you don't get this automatic interruption, and an opening arc may last longer, burning the contacts in the process. That's why relays are allowed to switch only a fraction of the AC power if DC.

It's not uncommon to see 250V AC relays only rated for 30V DC.

Why Starting Current of Induction Motor is High ???

Why High Starting Currents:

- Magnetizing

component circuit

- Resistance

and reactance circuit.

Resistance and leakage reactance circuit consist of resistance and leakage reactance of stator and rotor of induction motor connected in series. A load resistance (variable) is connected in series to the fixed rotor and stator impedance. During starting of the motor, slip will be one. Therefore if we calculate the total impedance offered (stator and rotor impedance) to the inrush currents during starting of induction motor which is minimum resulting in high inrush currents during starting of the motor.

Disadvantages of High Starting

Currents in Induction Motor:

Why LT motors are delta connected and HT motors are star connected ???

Working principle of 3Ph. Induction motor...

Induction motor is a generalized transformer...

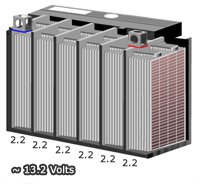

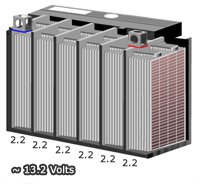

Why is My 12 Volt Battery Reading as 13 Volts?

Why is My 12 Volt Battery Reading as 13 Volts?

Source: https://www.batterystuff.com

What is Transimpesdence Amplifier ???

Quick note to Choose the right frame size of motors...

Detailed explanation of Battery Charging with Modes ....

A 5 V USB power source is commonly used in portable devices. A traditional USB port has a maximum output current of 500 mA for USB 2.0, or 900 mA for USB3.0, which is insufficient to rapidly charge a portable device. A USB adapter (dedicated charge port, or DCP) can increase the output current up to 1.8 A with a micro-USB connector. Unfortunately, a typical 5 V/2 A power adapter only provides a total of 10 W power capability. Using such a power adapter as a power source for the charger, the battery charger only provides up to 2.5 A charge current. This is not high enough to fast-charge a battery pack of 4,000 mAh and above. Can we continue to increase the output current of a 5 V power adapter in order to increase power? In theory, yes, if we increase the cost and use a special cable. However, there are some limitations:

Can we further reduce the charge time through some unique battery charging approach without increasing input power or charge current? To find out, let’s take a look at the battery-charging cycle.

To achieve a fast-charging function, use a higher power adapter like 9 V/1.8 A and 12 V/2 A. In addition to charging the battery, a battery charger also powers the system. It is one of the hottest spots in the portable power device. For a better end user experience, the maximum temperature rise between the device case and ambient temperature should not exceed 15°C. This is why the battery charger power conversion efficiency and system thermal performance become more critical. How do we achieve best thermal performance and efficiency?

Rapid charge is becoming ever more important in many portable devices. This requires new design considerations in the practical charging system, including a new type of high-voltage adapters, charge current and thermal optimization. Also required is an advanced charging profile to optimize charge time and improve battery life. The experimental results provided demonstrate the effectiveness of the design for rapid charge.

For more information about battery charge management, visit:

www.ti.com/batterycharger-ca.

Difference between unearthed cables and earthed cables and their relationship with Insulatuon level

Introduction:

- In HT electrical distribution, the system can be earthed or unearthed. The selection of earthed/unearthed cable will depend on system. If distribution system is earthed then we have to use cable which is manufactured for earthed system. (Which the manufacturer specifies). If the system is unearthed then we need to use cable which is manufactured for unearthed system. The unearthed system requires high insulation level compared to earthed System.

- For earthed and unearthed XLPE cables, the IS 7098 part2 1985 does not give any difference in specification. The insulation level for cable for unearthed system has to be more.

Earthed System:

- Earlier the generators and transformers were of small capacities and hence the fault current was less. The star point was solidly grounded. This is called earthed system.

- In Three phases earthed system, phase to earth voltage is 1.732 times less than phase to phase voltage. Therefore voltage stress on cable to armor is 1.732 times less than voltage stress between conductors to conductor.

- Where in unearthed system, (if system neutral is not grounded) phase to ground voltage can be equal to phase to phase voltage. In such case the insulation level of conductor to armor should be equal to insulation level of conductor to conductor.

- In an earthed cable, the three phase of cable are earthed to a ground. Each of the phases of system is grounded to earth. Examples: 1.9/3.3 KV, 3.8/6.6 KV system

Unearthed System:

- Today generators of 500MVA capacities are used and therefore the fault level has increased. In case of an earth fault, heavy current flows into the fault and this lead to damage of generators and transformers. To reduce the fault current, the star point is connected to earth through a resistance. If an earth fault occurs on one phase, the voltage of the faulty phase with respect to earth appears across the resistance. Therefore, the voltage of the other two healthy phases with respect to earth rises by 1.7 times. If the insulation of these phases is not designed for these increased voltages, they may develop earth fault. This is called unearthed system.

- In an unearth system, the phases are not grounded to earth .As a result of which there are chances of getting shock by personnel who are operating it.Examples : 6.6/6.6 KV, 3.3/3.3 KV system.

- Unearthed cable has more insulation strength as compared to earthed cable. When fault occur phase to ground voltage is √3 time the normal phase to ground voltage. So if we used earthed cable in unearthed System, It may be chances of insulation puncture. So unearthed cable are used. Such type of cable is used in 6.6 KV systems where resistance type earthing is used.

Nomenclature:

- In simple logic the 11 KV earthed cable is suitable for use in 6.6 KV unearthed system. The process of manufacture of cable is same. The size of cable will depend on current rating and voltage level.

- Voltage Grade (Uo/U) where Uo is Phase to Earth Voltage & U is Phase to Phase Voltage.

- Earthed system has insulation grade of KV / 1.75 x KV.

- For Earthed System (Uo/U): 1.9/3.3 kV, 3.8/6.6 kV, 6.35/11 kV, 12.7/22 kV and 19/33 kV.

- Unearthed system has insulation grade of KV / KV.

- For Unearthed System (Uo/U): 3.3/3.3 kV and 11/11 kV.

- 3 phase 3 wire system has normally Unearthed grade cables and 3 phase 4 wire systems can be used earthed grade cables, insulation used is less, and cost is less.

Thumb Rule:

- As a thumb rule we can say that 6.6KV unearthed cable is equal to 11k earthed cable i.e. 6.6/6.6kvUnearthed cable can be used for 6.6/11kv earthed system. because each core of cable have the insulation level to withstand 6.6kv so between core to core insulation level will be 6.6kv+6.6kv = 11kv

- For transmission of HT, earthed cable will be more economical due to low cost where as unearthed cables are not economical but insulation will be good.

- Generally 6.6 kV and 11kV systems are earthed through a neutral grounding resistor and the shield and armor are also earthed, especially in industrial power distribution applications. Such a case is similar to an unearthed application but with earthed shield (some times called solid bonding). In such cases, unearthed cables may be used so that the core insulation will have enough strength but current rating is de-rated to the value of earthed cables. But it is always better to mention the type of system earthing in the cable specification when ordering the cables so that the cable manufacturer will take care of insulation strength and de rating.